Lithium-ion batteries are a common power source for millions of consumer devices. But they are now being adopted for use with Uninterruptible Power Supply (UPS) applications, as a means of ensuring uptime for mission-critical infrastructure in data centers. For companies wishing to deploy distributed computing and edge networks, lithium-ion batteries are ideal for use with IT deployments in remote locations. Lithium-ion batteries offer more reliable performance, require less maintenance, and have a higher power density than lead-acid batteries. Lithium-ion batteries last 2-3 times longer than lead-acid batteries, resulting in fewer battery replacements and lower labor costs. Also, lithium-ion batteries include a Battery Monitoring System (BMS) and other features that help to ensure safe battery operation. While the initial cost of lithium-ion batteries is still higher than lead-acid batteries, this cost difference is shrinking. Lithium-ion batteries can now provide a lower total cost of ownership (TCO) than lead-acid batteries in as little as 5 years. Over the typical service life of a UPS, it is estimated that a lithium-ion battery system can provide a TCO savings of 50% or more.

If your company has a need to establish localized IT resources, you may be thinking of investing in and deploying multiple IT footprints in remote locations, as part of a distributed computing or edge network. For example, if you're a banking, financial, or retail company, you may want to set up IT deployments at branch offices or store locations. If you're an education or healthcare organization, you may want to deploy IT footprints on several college or hospital campuses over a wide geographic range. If you're an industrial company, you may want to establish edge computing infrastructure at several manufacturing facilities.

The venues used for hosting these localized IT footprints include small data centers, server rooms, and network closets. Often, these remote deployments will rely on a single-phase UPS to power their IT infrastructure – as opposed to a three-phase UPS, which is typical of larger facilities. But like their three-phase counterparts, single-phase UPS systems require a reliable stored energy source. They need a battery system that will operate correctly at the crucial moment when the UPS must deliver backup power to the load.

In the past five years, lithium-ion batteries have come into use as a stored energy source in traditional data centers. In this white paper, we'll look at how these types of batteries can also be used to support single-phase UPS systems in remote mission-critical environments and edge data centers.

On November 9, 2019, the Royal Swedish Academy of Sciences awarded the Nobel Prize in Chemistry to three scientists whose research in the 1970s and 1980s led to the development of today's lithium-ion batteries. The first two award recipients, M. Stanley Whittingham and John B. Goodenough of America developed the initial chemistries used in lithium-ion batteries; the third, Akira Yoshino of Japan, created the first commercial rechargeable lithium-ion battery, which was adopted in 1991 by Sony for powering hand-held camcorders.

Thanks to these scientists, lithium-ion batteries are now common in everyday consumer products, powering everything from cell phones, laptops, and power tools to hybrid and self-driving vehicles. Lithium-ion batteries also serve as a backup resource for electrical grids and are coming into use as a storage solution for carbon-free energy sources such as solar panels and wind turbines. And within the past five years, manufacturers have developed lithium-ion battery solutions that are specifically designed for UPS applications in data centers.

In traditional data centers, the battery system is an important fail-safe device. In the event of a power outage, strings of batteries provide power to the UPS during the several minutes of ride-through time in which the data center switches over to an auxiliary power source, such as a second utility feed or generator.

But in edge data centers or remote IT deployments, the function of the battery may be slightly different. In many cases, the battery system IS the auxiliary power source for that facility. If a power outage occurs, the batteries may provide backup power to the UPS for 30 minutes or more. Without alternative power capability, these remote sites rely on stored energy from the UPS batteries to provide adequate time for the utility to be restored, or for IT administrators to migrate virtual IT environments to stable sites, or for the operations systems to conduct an automatic controlled power shutdown of connected equipment.

In either case, for traditional or remote data centers, the purpose of the battery system is the same. The battery helps to ensure uptime by keeping the IT infrastructure operational. As such, a traditional, remote, or edge facility must have a reliable battery system to ensure continuous operation of the UPS, and ongoing availability of the IT equipment.

Until recently, lead-acid batteries have been the go-to source for providing stored energy for UPS applications. The most common types of batteries used in data centers are Valve-Regulated Lead Acid batteries or VRLAs.

But lead-acid batteries have drawbacks that make them risky and expensive to use in data centers. Most data center owners and engineers will tell you that lead-acid batteries are the weakest link in their power distribution chain. They are the element that is most likely to fail at the moment when they are most needed.

It's hard enough to deploy and manage lead-acid batteries in traditional facilities. But when VRLA batteries are used in remote facilities and edge data centers, these same drawbacks produce a new set of problems that increase the trouble and cost of using them. The drawbacks include:

UPS units are powered by strings of lead-acid batteries, in which any individual battery can be a point of failure. If just one battery fails, it can bring down the data center's entire UPS system.

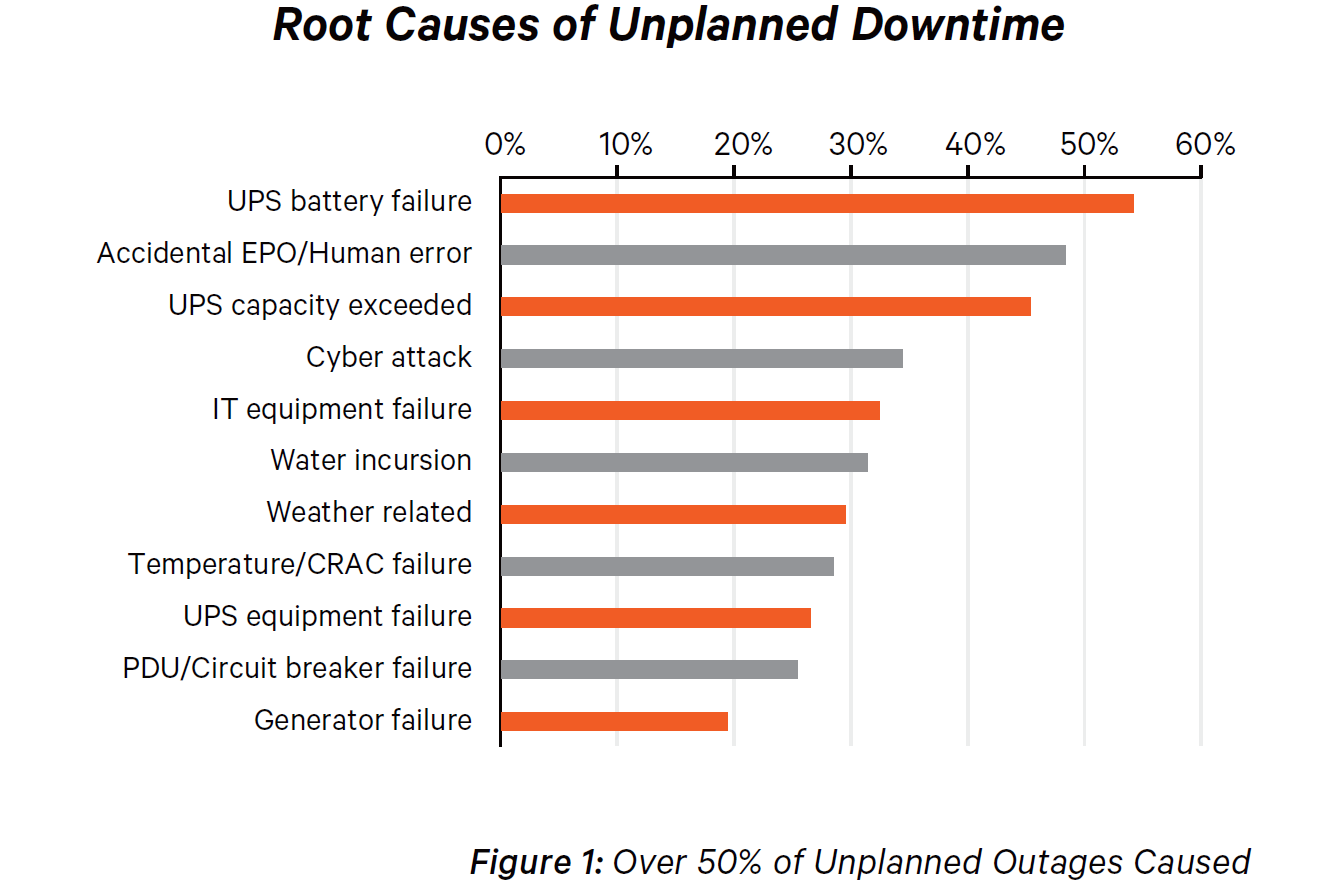

A 2013 study by the Ponemon Research Institute found that 55% of unplanned data center outages, and one-third of all UPS system failures, were due to failure of VRLA batteries. (NOTE: While this study was focused on traditional data centers, we see very similar characteristics of downtime in edge applications.)

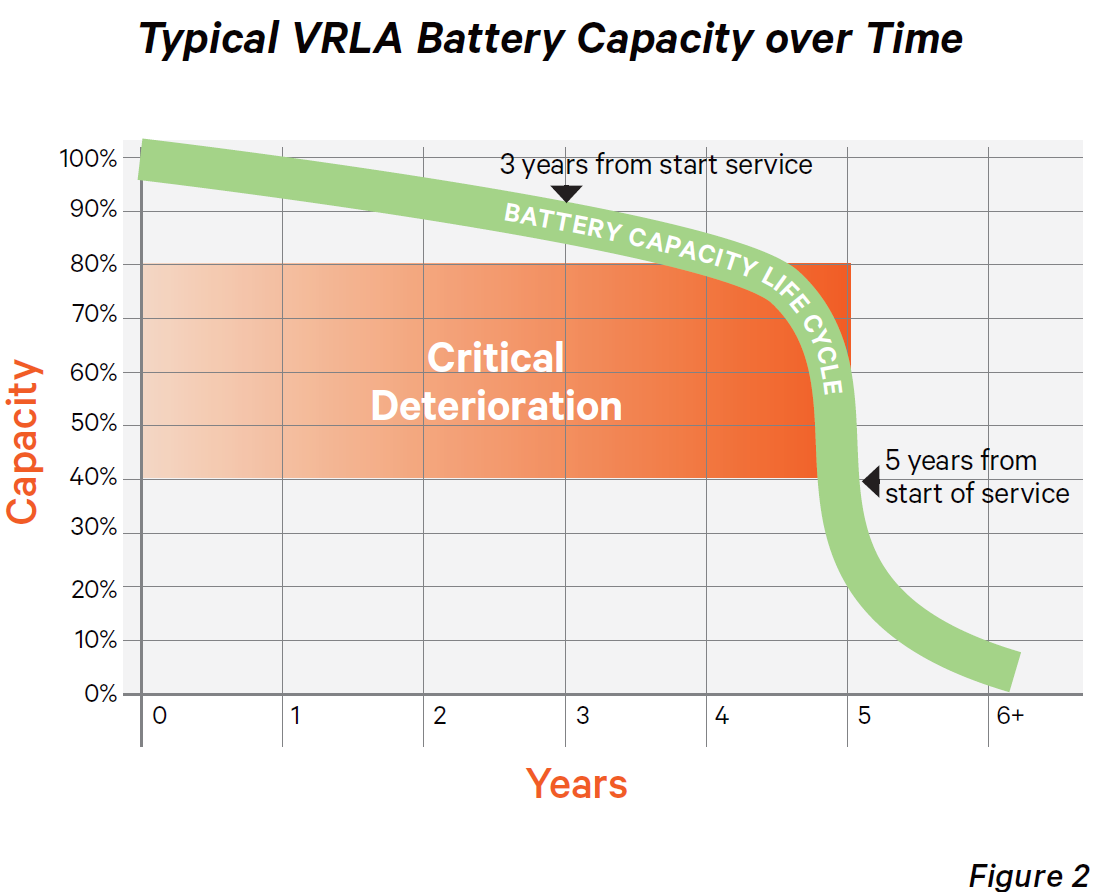

Lead-acid batteries must be replaced every 3-5 years. Their useful service life is determined by how often the batteries are discharged and recharged. But factors such as overcharging, frequent discharge cycles, strained battery terminals, loose connections, and higher ambient temperatures in the facility can shorten the battery's useful life. When the battery reaches 80% capacity, it is considered the end of life (EOL). Performance degradation typically accelerates at this point, the battery loses its ability to provide sufficient voltage.

As seen in Figure 2, after three years of use, the VRLA battery's capacity begins to drop off. This drop becomes even steeper after five years of use. Older batteries may be vulnerable to "sudden death syndrome," in which a battery works fine one day, but fails to provide sufficient power the next day, resulting in a UPS failure and data center downtime.

The short useful life combined with their potential for failure means that lead-acid batteries must be replaced every 3-5 years or 2 to 3 times over the 10-year life of your UPS. Preventive maintenance windows are widely used to replace entire battery systems, based on the amount of time the batteries have been in use. Datacenter owners and engineers face a perpetual replacement cycle when they deploy VRLA batteries in high quantities.

The ongoing cost of replacement and labor expenses adds to the TCO of the battery system. These expenses are further magnified when lead-acid batteries are used in multiple remote locations. Often, you must factor in additional costs of travel time, shipping, and transportation in sending new batteries out to the remote facilities, and in sending maintenance personnel out to install them.

Lead-acid batteries require valuable rack space that might otherwise be used for IT infrastructure. This is a problem in any IT environment, but especially in small, remote facilities such as server rooms, network closets, and containerized units, where space for IT servers is even more limited. Also, lead-acid batteries are heavy and difficult to move, which adds to the labor time and cost for installing or replacing the batteries in remote facilities.

The useful life of a battery is strongly affected by the battery's operating temperature, even if the battery is not experiencing charging and discharging cycles. With lead-acid batteries, a controlled room temperature of 77°F (25°C) is necessary, in order to ensure a 3–5-year lifespan. With every 5°C increase in room temperature, the useful life of a typical VRLA battery is cut in half.

While the cost of cooling in any data center facility adds to the TCO of the batteries, it's even harder to control temperatures in remote facilities.

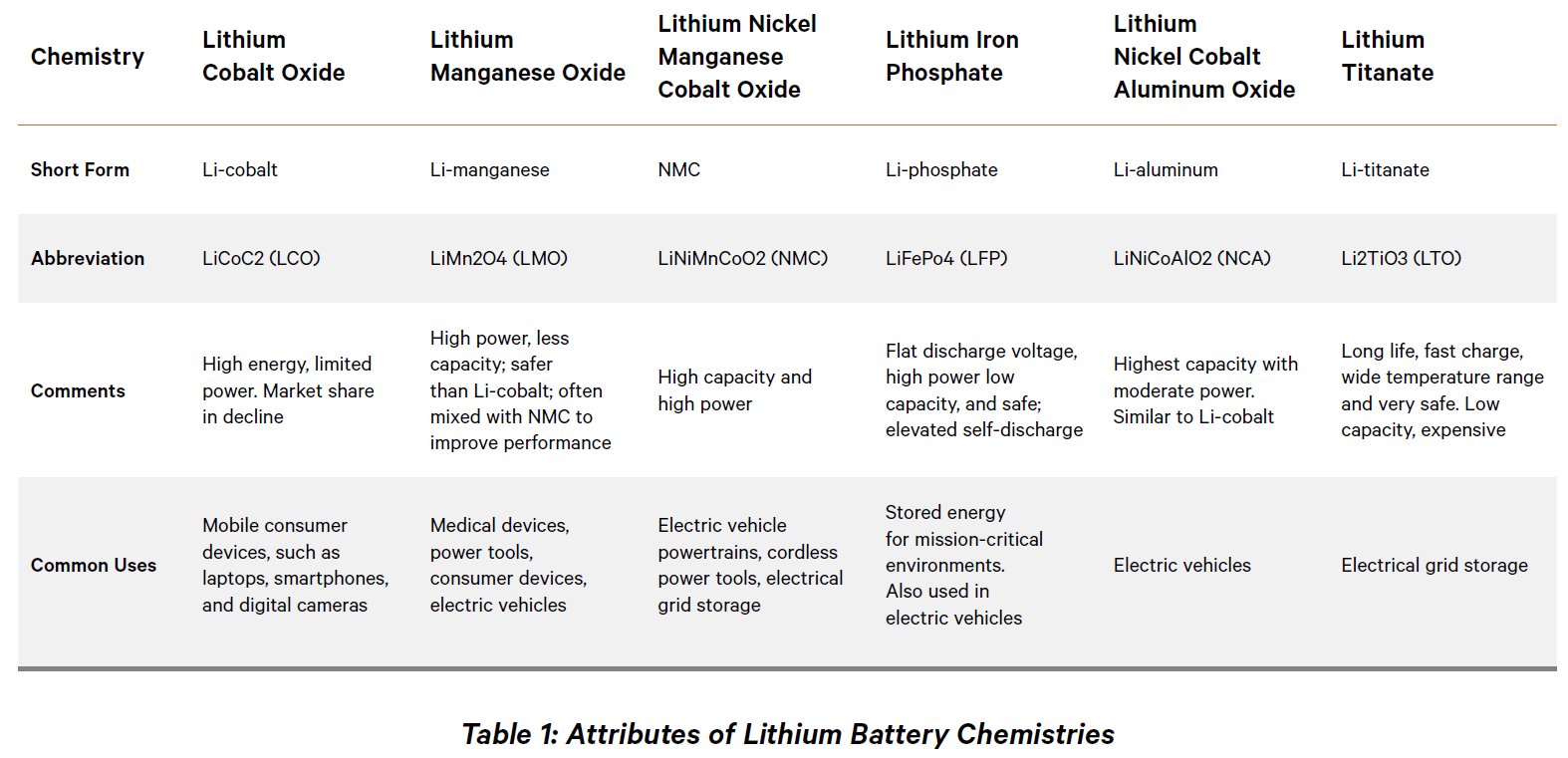

Lithium-ion batteries have many uses, but not all lithium-ion batteries are the same. Table 1 below shows the different types of chemistries used in lithium-ion batteries and the applications for each type of battery.

Within the past five years, manufacturers have developed lithium-ion battery solutions for specific use with UPS applications. Lithium-ion batteries have become a viable alternative source of stored energy, due to their improved performance, the flexibility of use, and reduced TCO over lead-acid batteries.

The lithium battery chemistries used in UPS applications are lithium iron phosphate (LiFePO4, or "LFP" for short), lithium manganese oxide (LiMnO2 or "LMO"), and lithium nickel manganese cobalt oxide (LiNiMnCoO2, or "NMC"). There is also a UPS battery that uses an LMO/NMC blend to improve performance.

(NOTE: For an in-depth look at the properties of the LFP, LMO, and NMC chemistries, see the Vertiv application report, "The Emergence of Lithium-Ion Batteries Within the Data Center.")

The manufacturers of lithium-ion batteries that are qualified for UPS applications utilize improved battery design, quality materials, and superior manufacturing methods. With a longer lifespan and reduced maintenance requirements, the failure of lithium-ion batteries in mission-critical environments is extremely rare.

Also, all lithium-ion batteries include a built-in battery management system (BMS), which provides fault monitoring, cell balancing, and power optimization capabilities for each individual battery. The BMS helps to maximize battery life and minimize downtime.

Lithium-ion batteries typically have a design life of 8-10 years, which means they should have the same lifespan as a single-phase UPS. When a VRLA battery is at 80% capacity or EOL, the lithium-ion battery is still at 93% capacity.

This eliminates the pain of replacement since lithium-ion batteries don't have to be replaced every 3-5 years, which means huge cost savings. Also, lithium-ion batteries can be fully charged and stored for greater lengths of time than VRLA batteries, with minimal impact on the battery's lifespan.

Lithium-ion batteries weigh about 45% less than lead-acid batteries. This makes the batteries easier to transport and install in remote facilities.

Lithium-ion batteries can be up to 70% more compact than lead-acid batteries. This provides space savings in any on-site or remote facility, allowing you to reconfigure your deployment to increase available rack space for IT servers and networking equipment.

Lithium-ion batteries have a higher energy density (Wh/kg, or watt-hours per kilogram) and power density (W/kg, or watts per kilogram). They offer the same amount of energy as lead-acid batteries, but with a smaller size and lower weight.

Lithium-ion batteries for UPS applications are designed to operate at higher temperatures than lead-acid batteries, and warmer temperatures will have less impact as a result. You can operate most lithium-ion batteries at temperatures of 86°F (30°C) – which is almost 10 degrees higher than lead-acid batteries – without degradation or reducing calendar life. This allows you to increase room temperatures in data centers or remote server rooms, which lowers cooling costs by reducing energy used for cooling.

Lithium-ion batteries can typically be recharged to 90% capacity in under 2 hours for rack-based systems, whereas VRLA batteries may take up to 6 hours to reach the same level, and up to 24 hours to fully recharge. If the data center has several outages in short succession, the lithium-ion battery can recharge fast enough to provide ride-through time for each outage.

Until recently, the high initial cost of lithium-ion batteries was a hindrance to their adoption for UPS applications. But in the past five years, this cost has been significantly reduced. Today, the initial capital investment for a lithium-ion battery system for remote facilities or edge data centers is, on average, between 1.75x and 2.25x the cost of a VRLA battery system for these same facilities. Additional price reductions are expected over the next decade as lithium-ion batteries come into more widespread use in data centers.

Compared to VRLA batteries, lithium-ion batteries offer long-term savings for data center owners in reduced operating costs, resulting in a lower TCO. As mentioned, lithium-ion batteries have an estimated design lifespan of 8-10 years, which may be equal to that of your single-phase UPS. This eliminates the cost of replacing lead-acid batteries every 3-5 years and also eliminates the shipping, travel, and labor costs required to replace VRLA batteries in remote data centers.

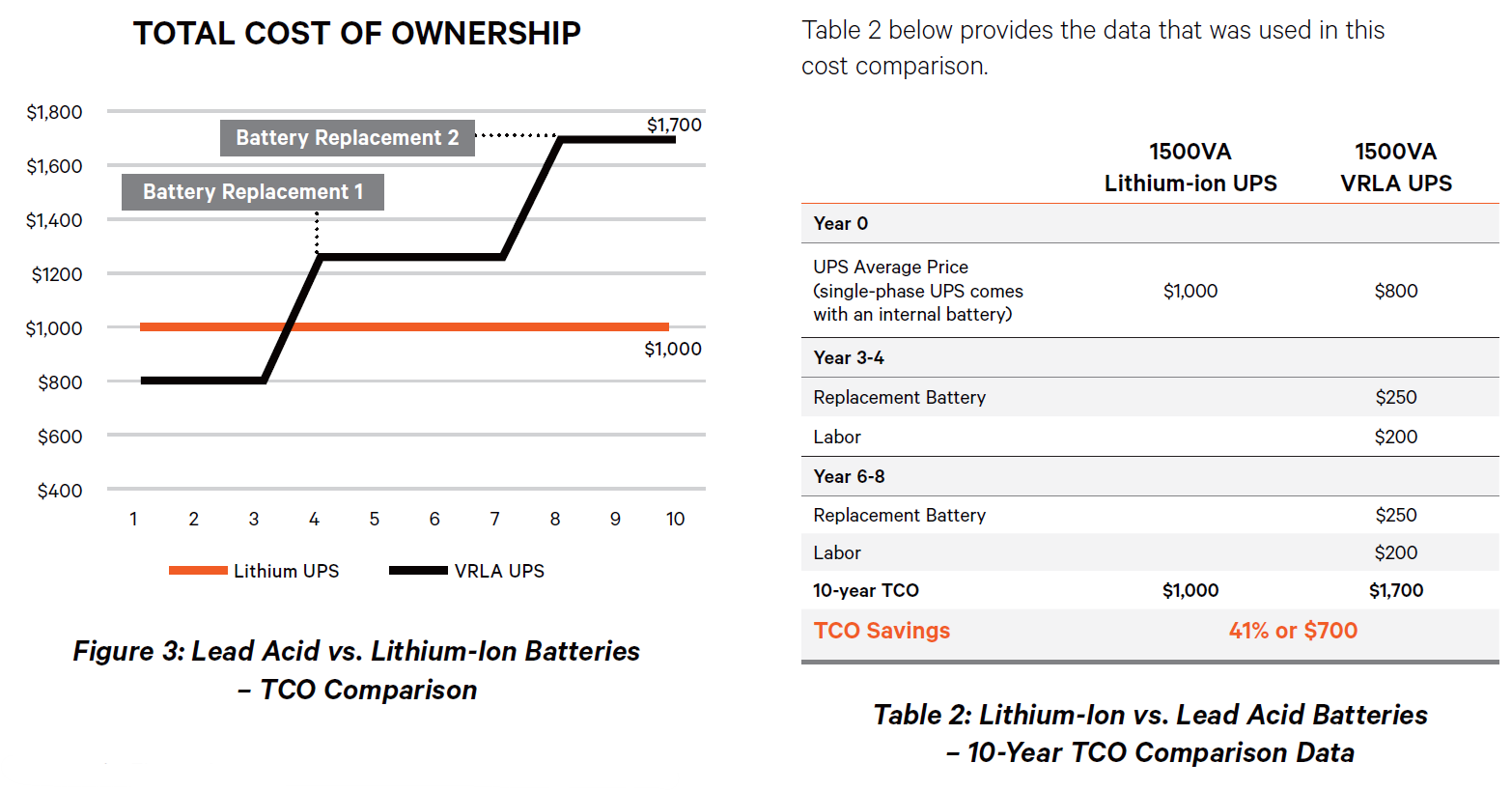

A recent evaluation test conducted by Vertiv compared the TCO of lead-acid and lithium-ion batteries used in single-phase UPS applications. The cost comparison looked at initial cost and battery replacement costs from a variety of leading manufacturers over a 10-year timespan for VRLA and an industry leader for lithium-ion batteries.

As seen in Figure 3, the study revealed that while the initial costs of VRLA systems are lower, the operating costs increase steadily over the 10-lifespan of the UPS, with significant bumps in cost every few years, each time the batteries have to be replaced. By contrast, while the initial costs of a lithium-ion battery system are higher, the overall costs remain relatively steady over this same 10-year period. The lithium battery system shows a return on investment (ROI) within five years, beginning just before and/or after the first VRLA replacement cycle. In relative dollars, the lithium battery system is more cost-effective over the long run.

Again, the initial cost of a UPS with a lead-acid battery is lower, but the TCO increases over the 10-year period. During this time, the UPS will typically require at least two battery replacements, as each VRLA battery reaches EOL.

On the other hand, the initial cost of the UPS with a lithium-ion battery is higher. But over its 10-year lifespan, the UPS does not require battery replacement, as the lithium-ion battery continues to function. After 10 years, using lithium-ion batteries results in a TCO savings of $700, or 41%.

Yes. Lithium battery solutions that are used in UPS applications have a BMS that monitors critical parameters (such as temperature, voltage, and current) at the cell level, ensuring safe and reliable operation throughout the life of the system.

All types of batteries are vulnerable to a condition known as thermal runaway. This occurs when the chemistry inside a battery cell reaches such a high temperature that it exceeds its ability to disperse heat, resulting in a failure.

However, for the lithium chemistries used in UPS applications, the thermal runaway temperatures are higher than 200°C (400°F). Most lithium-ion batteries have a control temperature limit of around 70ºC (158ºF), due to life considerations. When the battery reaches this control temperature limit, the Battery

Management System will automatically disconnect the battery from the UPS load or charger. In other words, the BMS will disconnect the battery at a low threshold, long before the battery reaches its thermal runaway temperature.

Also, today's leading battery manufacturers create quality lithium-ion batteries for UPS systems, with durable battery designs and cell packaging. The batteries include safety fuses, overcharge protection, and hardened material layers. Most lithium-ion batteries are manufactured in compliance with UL and other applicable safety standards.

The cost analysis and performance data clearly show why lithium-ion batteries are the better-stored energy source for single-phase UPS systems. Over a 10-year UPS lifespan, lithium-ion batteries provide significant TCO savings, by eliminating the pain of replacement that comes with lead-acid batteries. The longer lifespan and reduced maintenance needs of lithium-ion batteries produce a significant ROI for IT

Managers in less than five years.

The smaller size and reduced weight of lithium-ion batteries provide better flexibility for use in remote facilities. And with superior performance, lithium-ion batteries can help to ensure uptime and continuous operations for your IT deployments.

The combined advantages in cost-effectiveness, performance, and safety will be well worth the initial investment, as lithium-ion batteries will provide dependable long-term service to your mission-critical IT infrastructure in server rooms, network closets, and edge data centers.

To learn more about how lithium-ion battery solutions can be used with UPS applications in remote facilities and edge data centers, visit us at Vertiv.com.